End Grain and Fresh Cut Protection

End grain and fresh cut sealing is an important tool for any woodworker or deck builder looking to protect and extend the life of their projects. The end grain of a piece of wood is one of the most porous and vulnerable parts, and if left unsealed, can easily soak up moisture, leading to warping, splitting, and cracking. But with the right end grain sealer, you can prevent these issues and keep your wooden project looking great for years to come.

Why is the end grain so vulnerable? When a piece of wood is cut – including turning blanks – the wood grain is exposed, revealing thousands of tiny pores that can easily absorb moisture. This moisture can cause the grain to swell, leading to warping and other problems. And once the grain has absorbed moisture, it is much more difficult to get it out, which can lead to rot and other forms of degradation.

Even composite or other decking and fence material can be susceptible to moisture intrusion and swelling! The same as wood, sealing the fresh cuts simply makes sense to avoid any future issues.

To prevent these problems, woodworkers and carpenters have been applying end grain sealers for centuries. End grain sealers are specially designed to penetrate into the wood grain and form a moisture barrier. They work by filling the pores in the end grain, preventing moisture from entering and causing damage.

There are many different types of end grain sealers available, each has its own set of pros and cons, and the right choice will depend on the specific needs of your project. Some woods, such as exotic hardwoods, cedar and redwood, are naturally resistant to moisture; however, it is highly suggested to seal any wood species (and composite) fresh cuts and end grain for long-term sustainability.

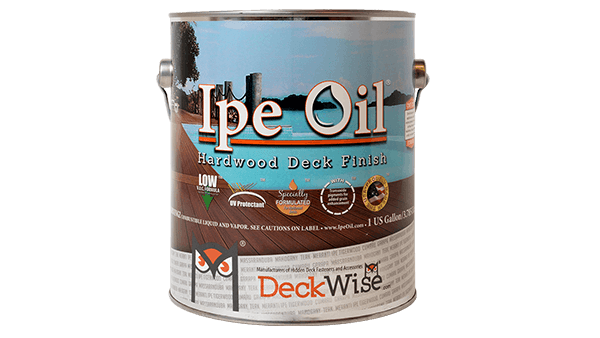

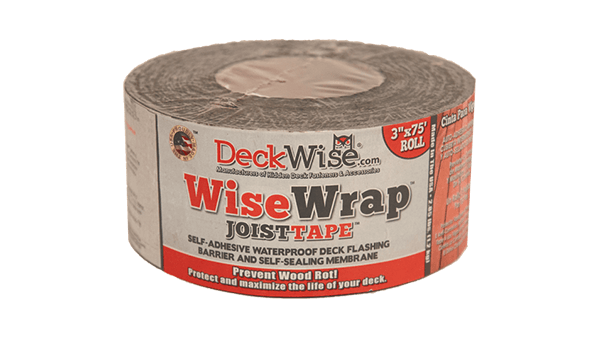

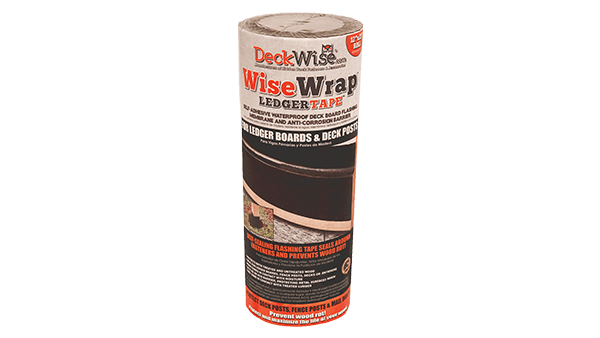

Check out the DeckWise® end grain sealant here for starters!