-

- Hidden Deck Fasteners

-

Hidden Deck Fasteners

- Products

- Products

-

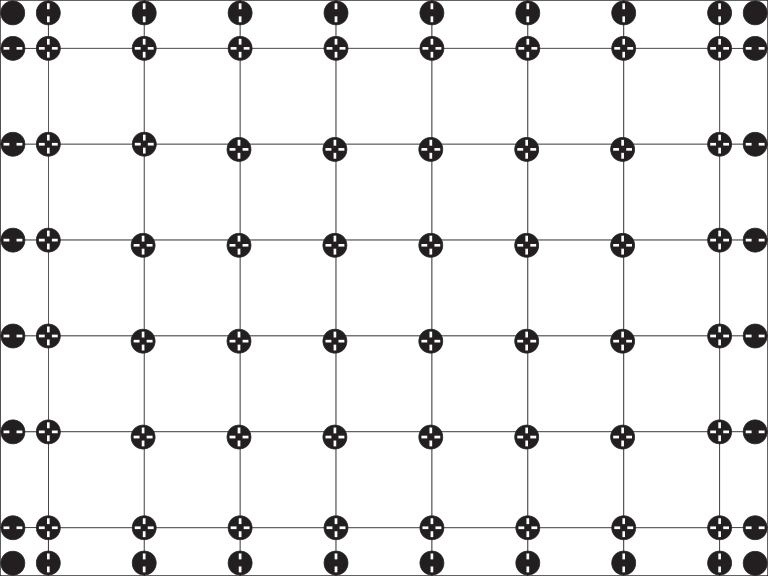

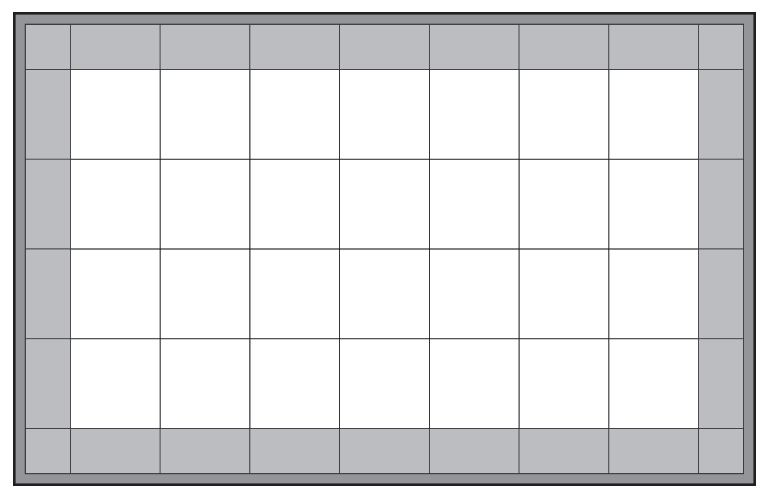

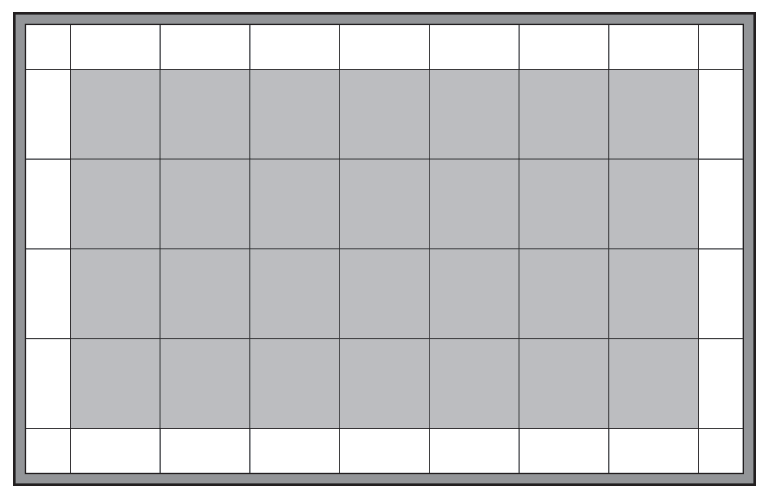

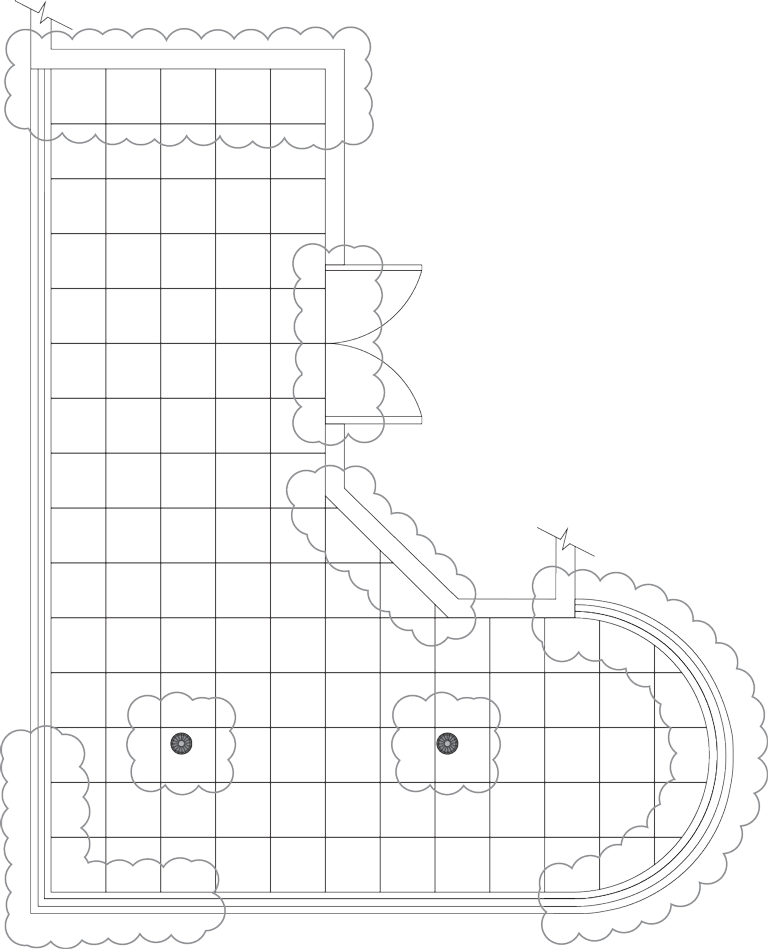

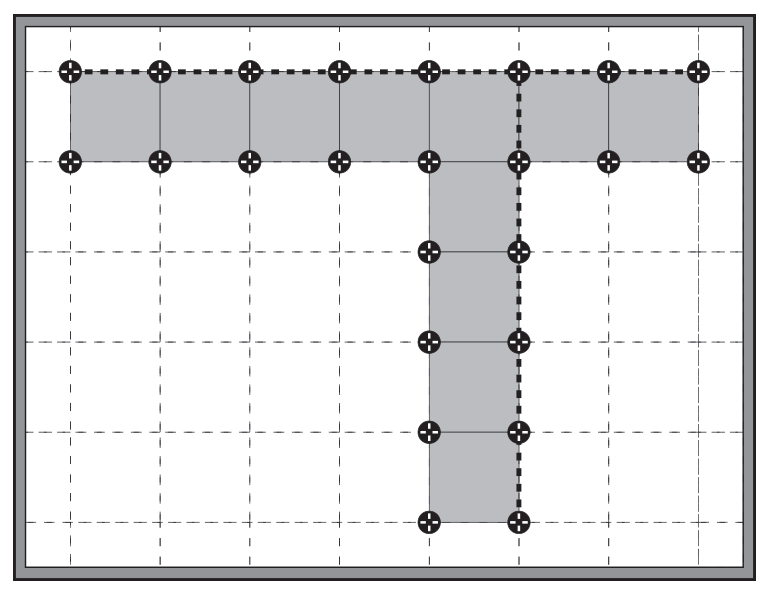

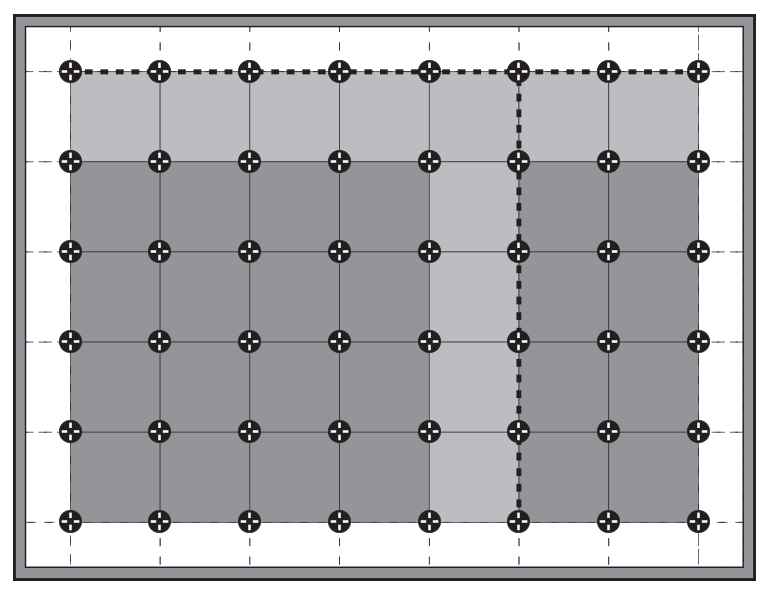

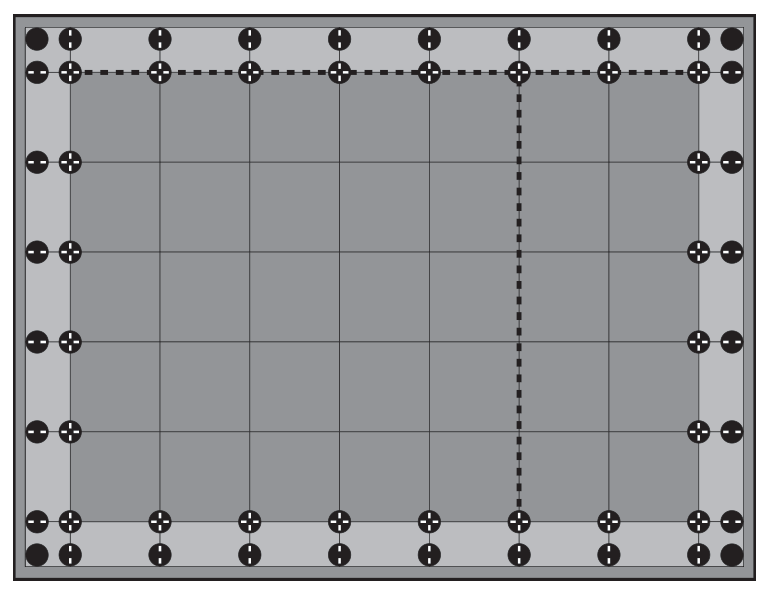

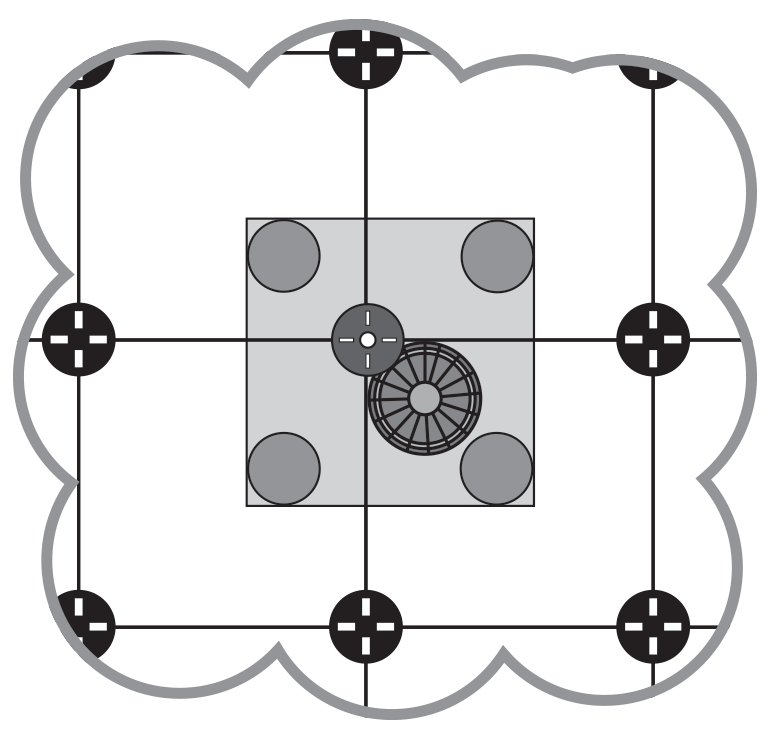

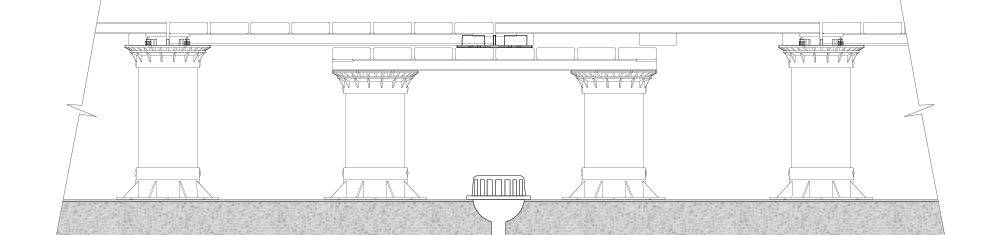

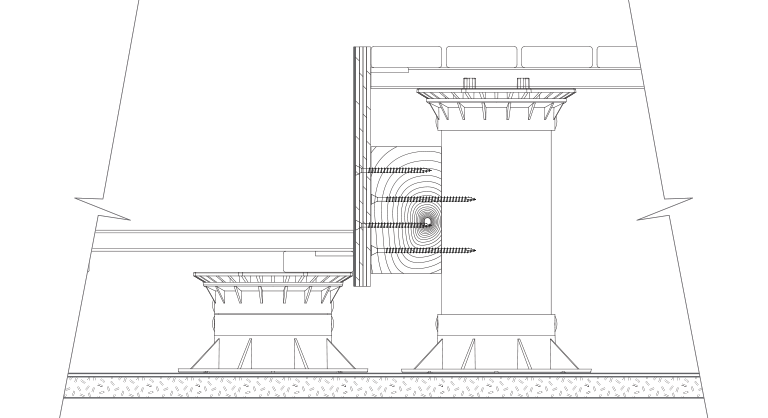

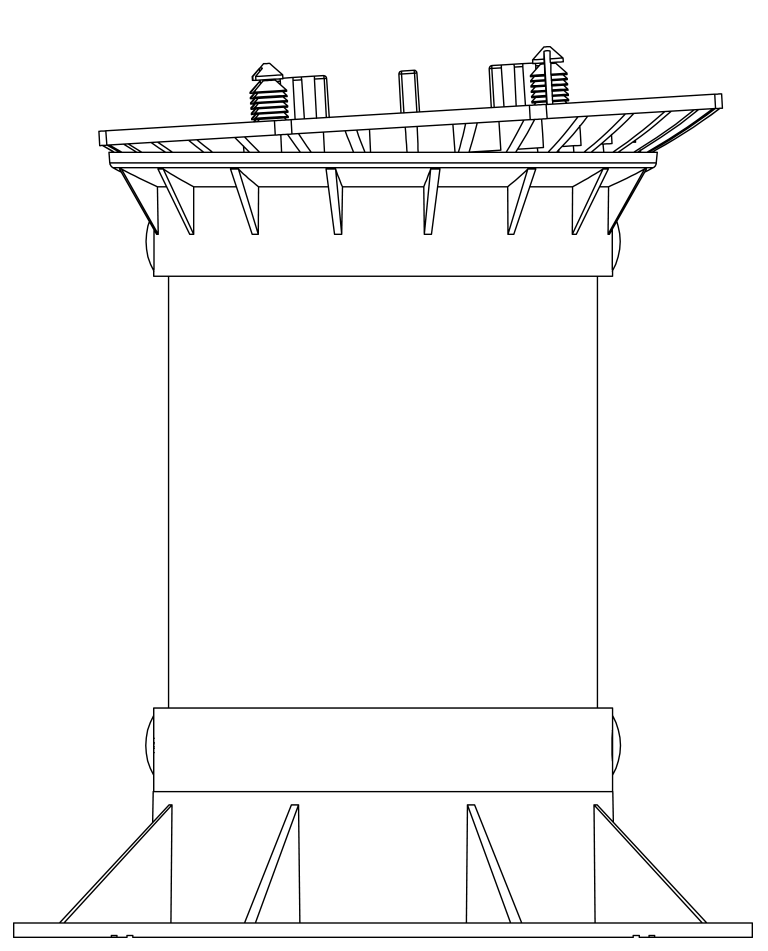

Hidden Deck Fasteners

Deck Screws

Finishes

Decking

Concrete

Deck Tools

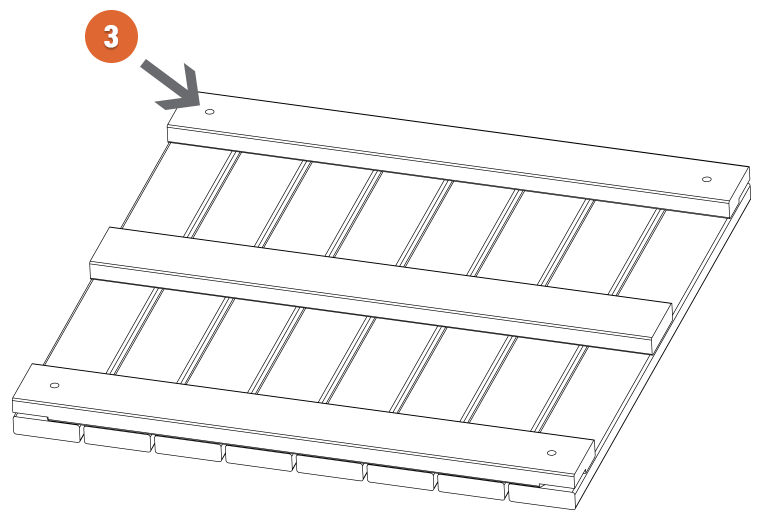

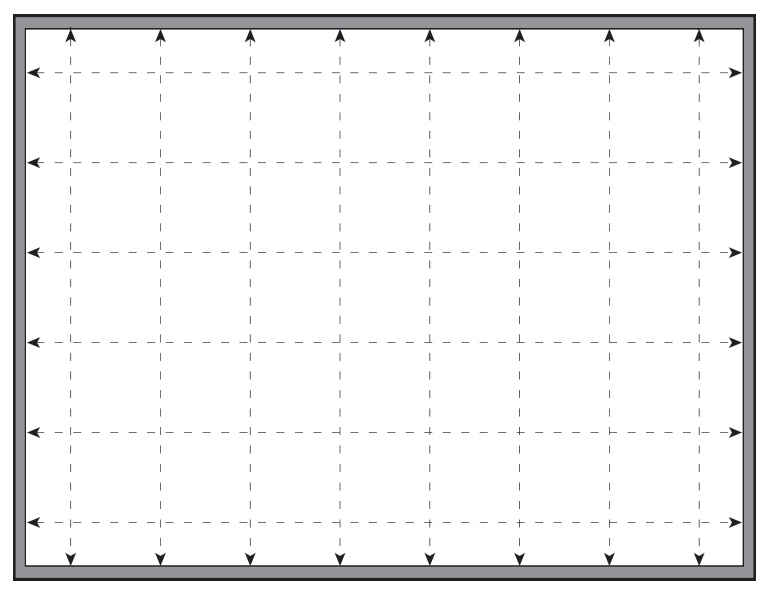

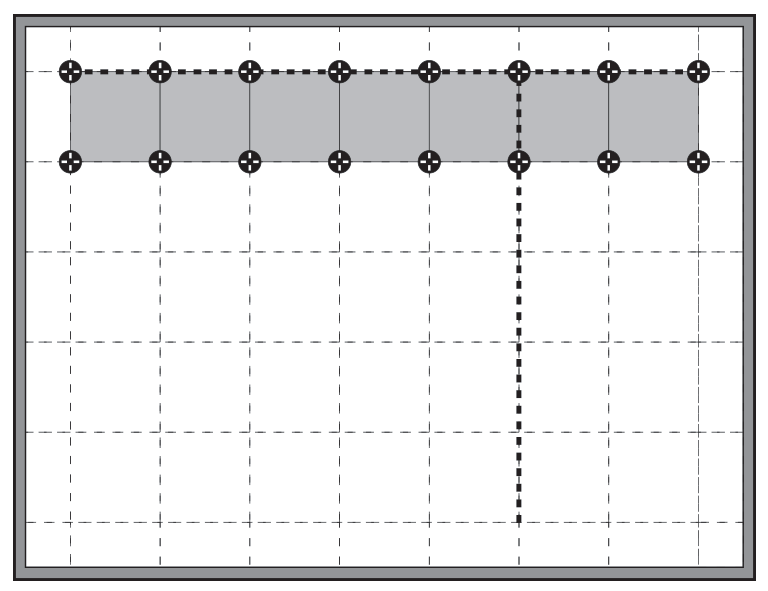

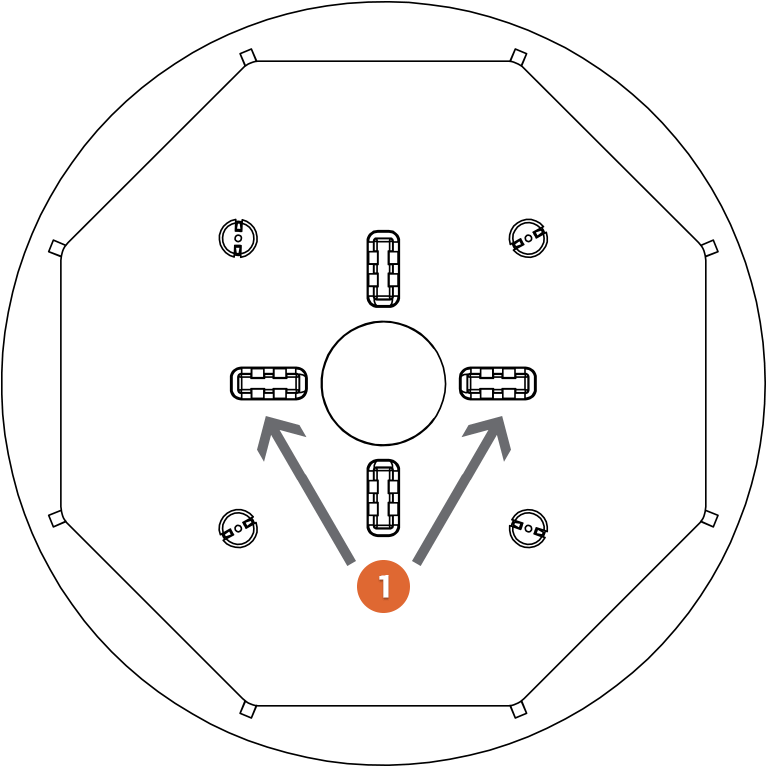

Deck Tile Systems

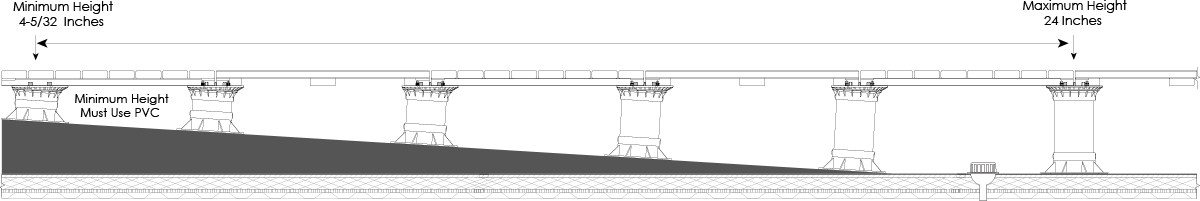

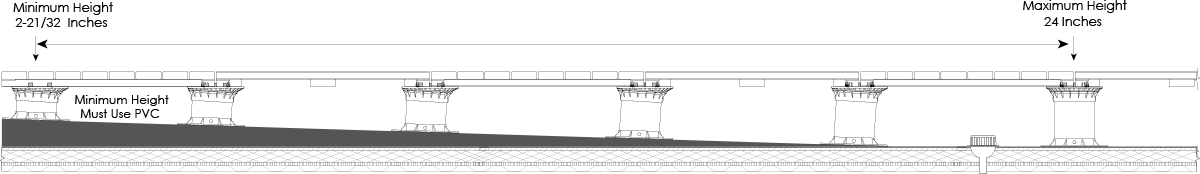

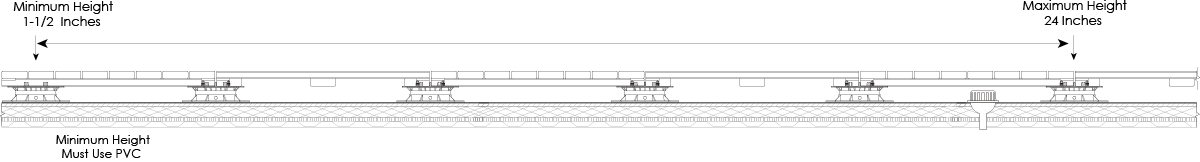

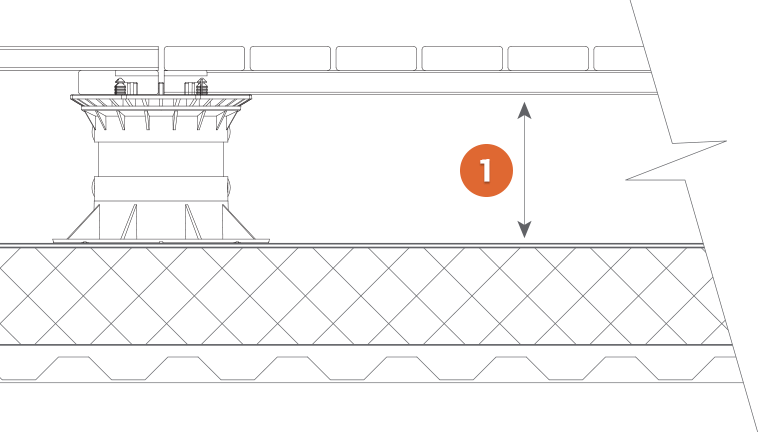

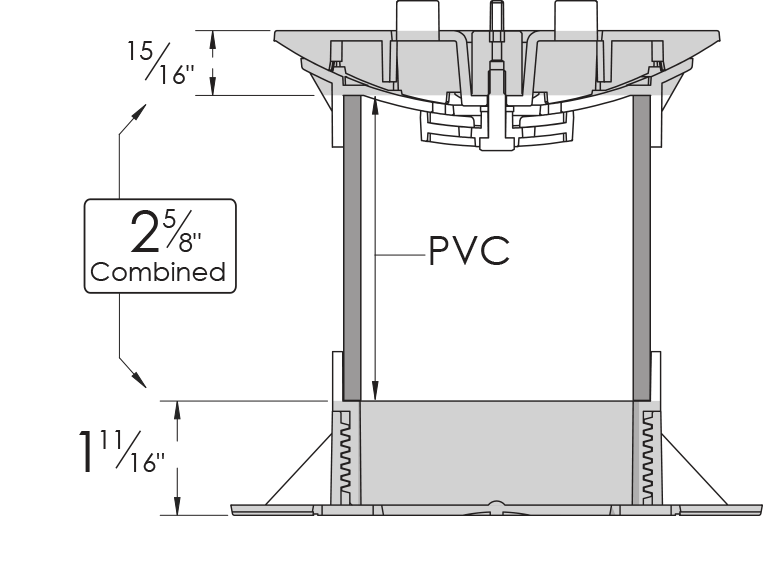

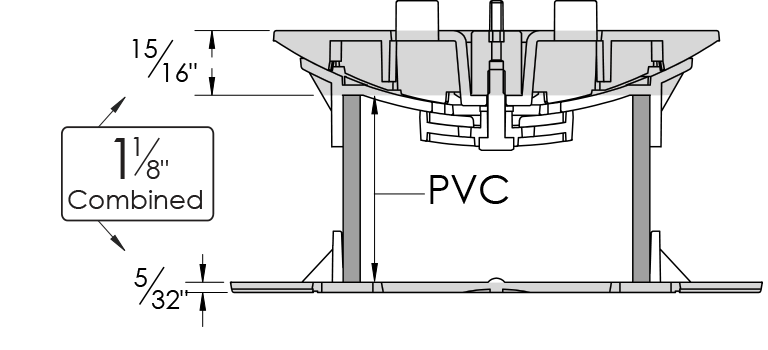

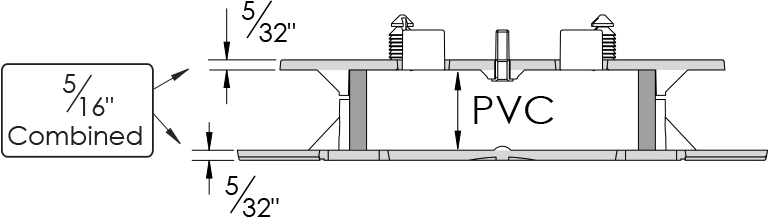

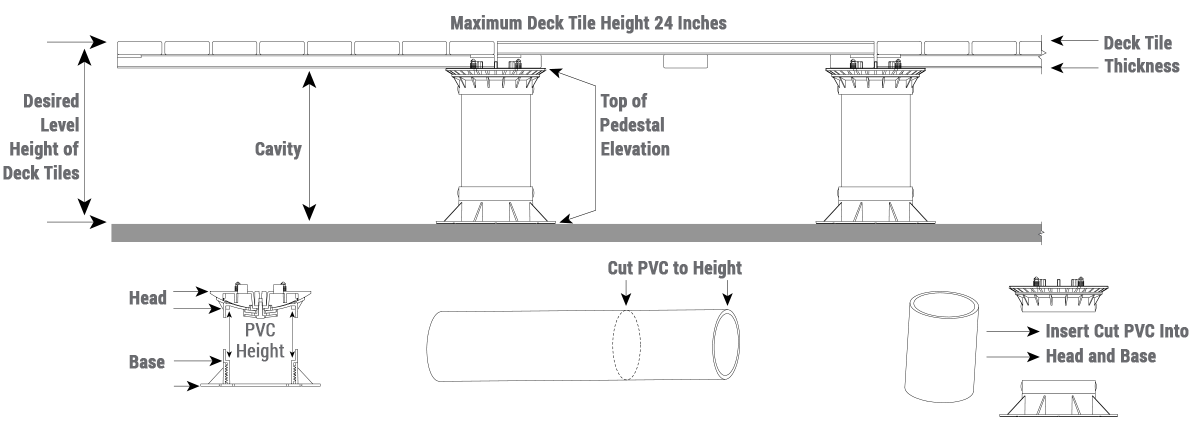

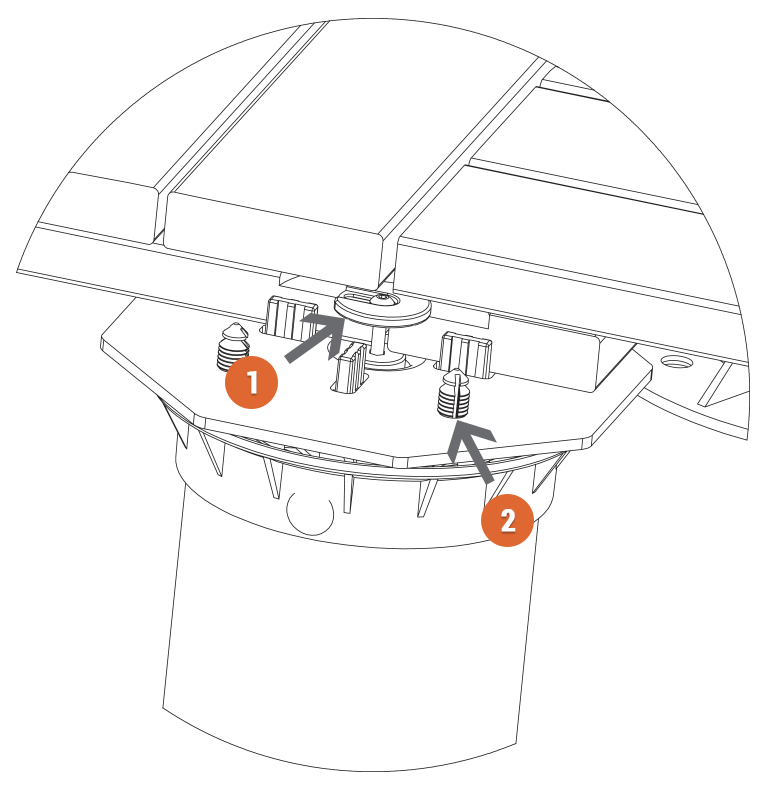

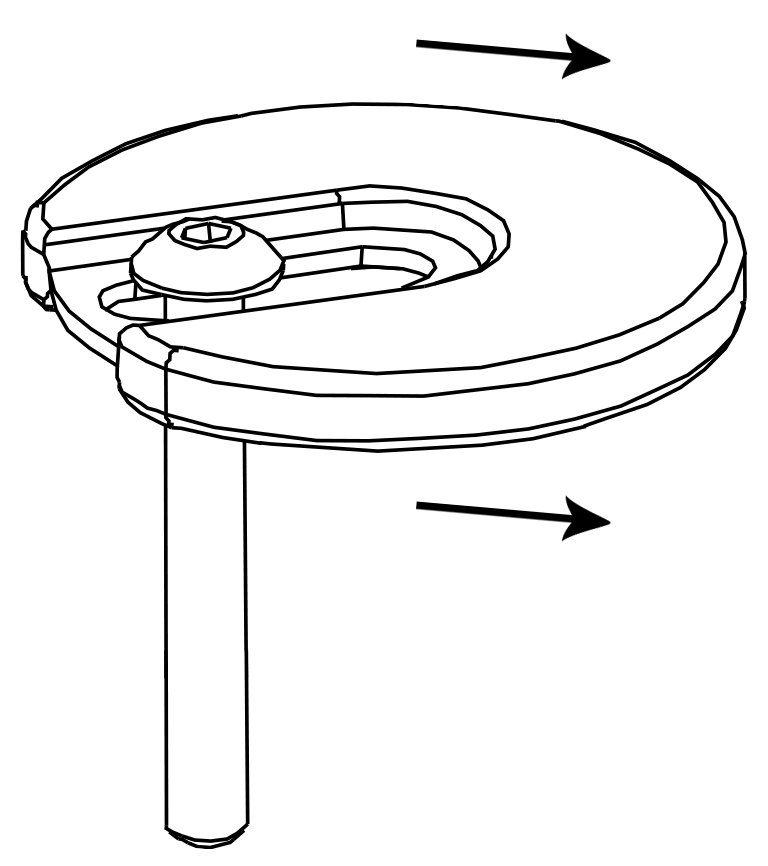

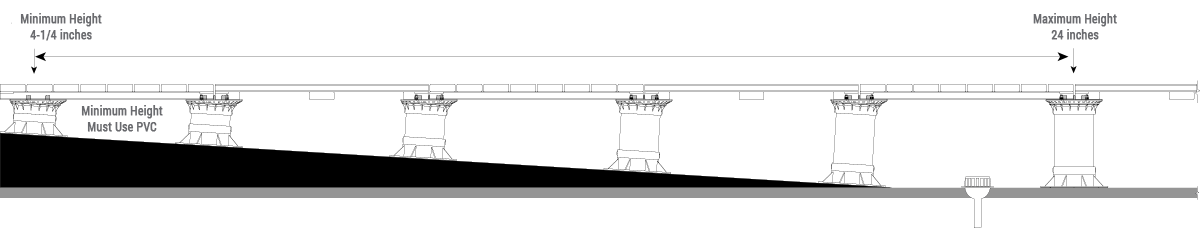

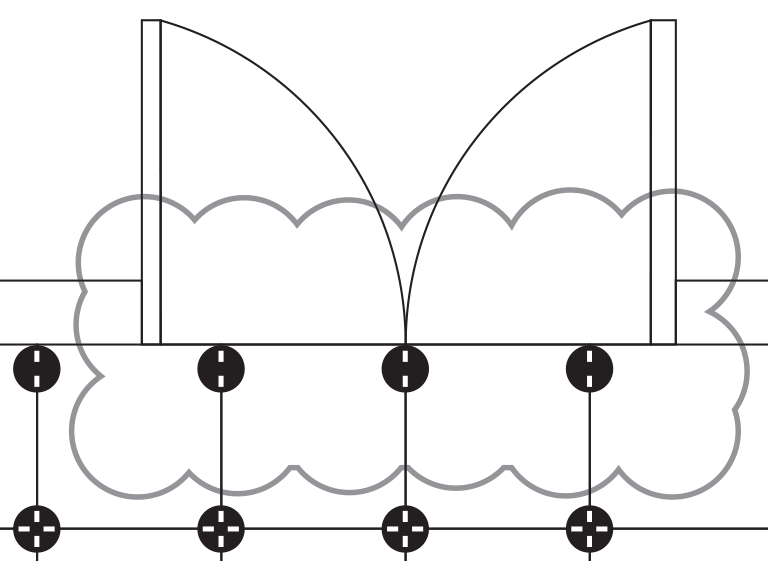

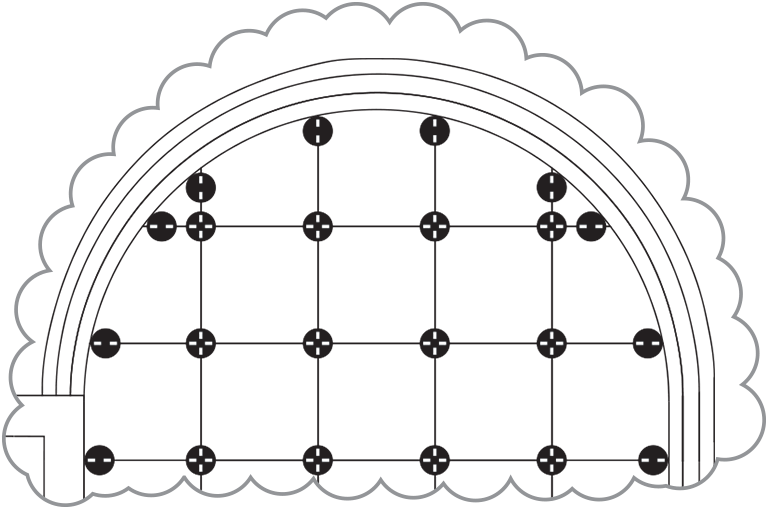

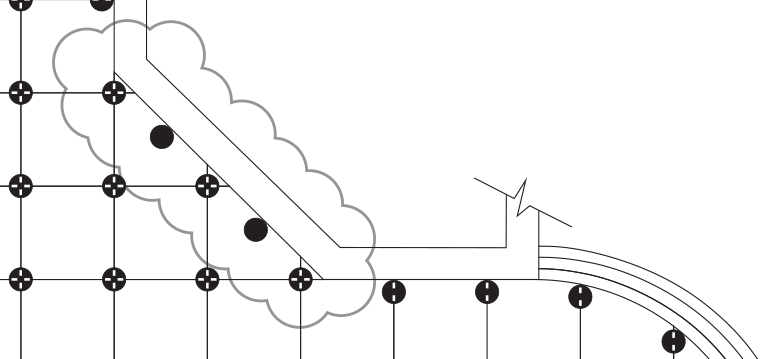

Altitudes Pedestals

Hidden Siding Clips

Wood Care & Maintenance

Deck Cable Railing

Epoxy & Colorants

-

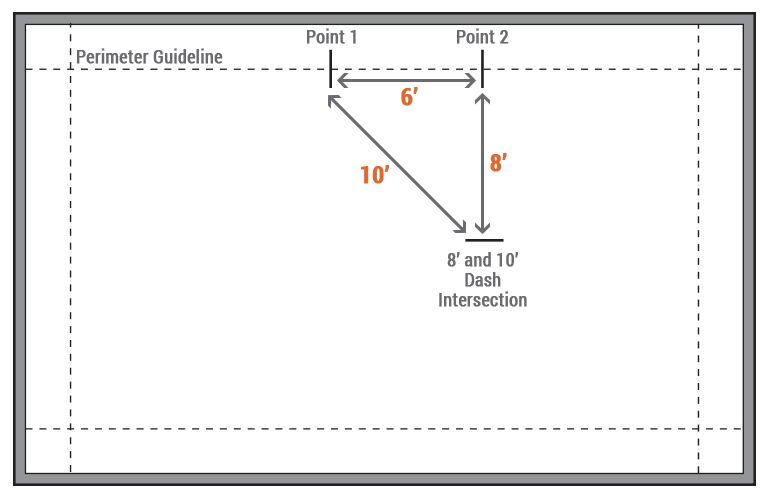

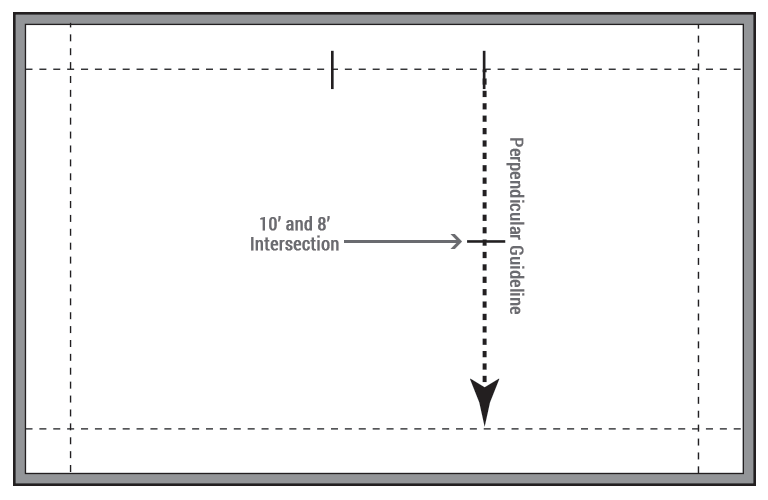

- Install

- Dealers

- Warranty

- Contact